Casing Tally Preparations & Excel Sheets

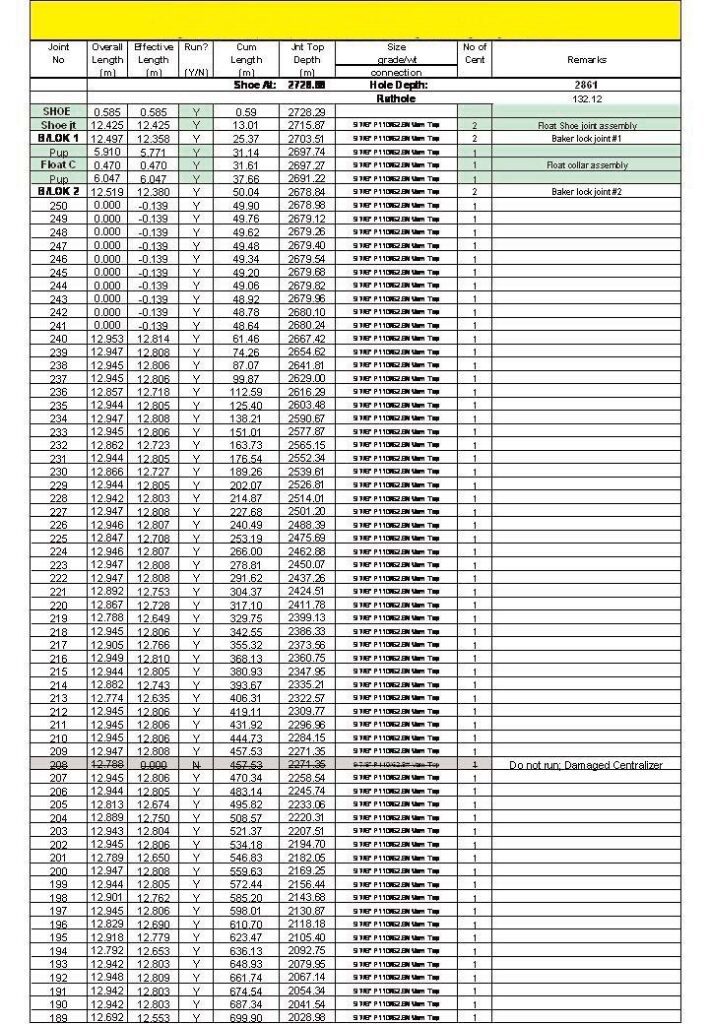

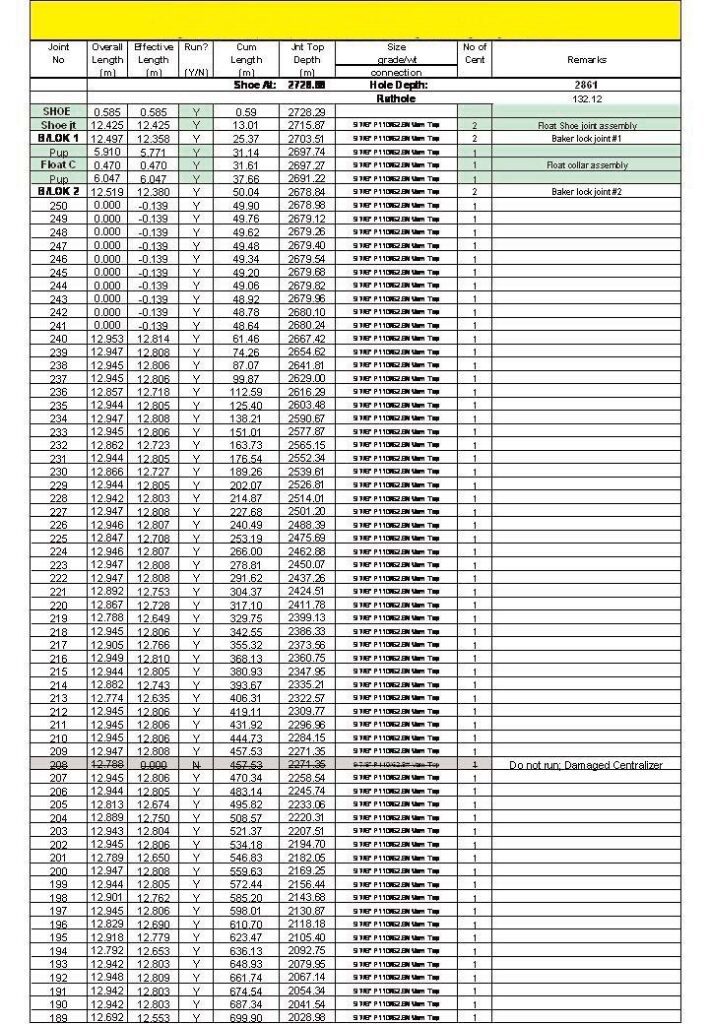

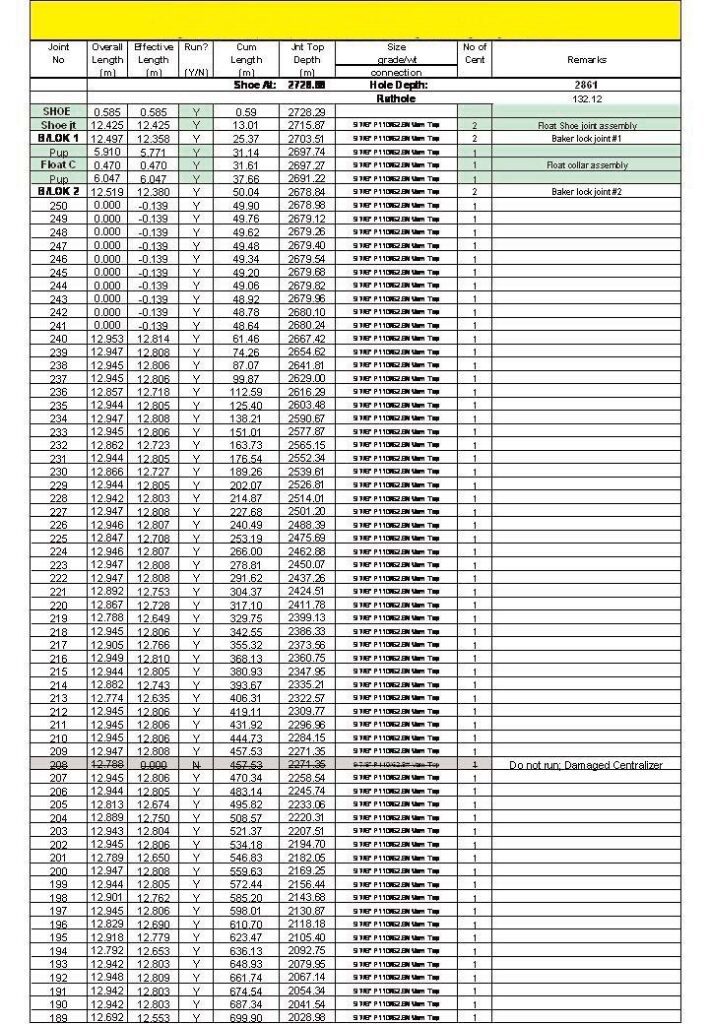

There are two different types of tubular tallies: 1) a casing tally spreadsheet and 2) a casing liner tally.

A casing tally works from a fixed point at the wellhead (e.g. hanger landing point) and the formulae in the spreadsheet calculate the shoe depth by adding the length of each joint below the wellhead to the shoe.

A liner tally is run until the shoe tags the bottom of the hole, then the liner is picked up 2m. The known depth for a liner tally (fixed point) is therefore the liner shoe depth which is equal to the total depth of the hole drilled minus a rathole, e.g. 2m. The liner tally works from a fixed point at the shoe and the formulae in the spreadsheet calculate the liner hanger system and packer depths by subtracting the length of each joint above the shoe back to the top of the liner hanger/polished bore receptacle.

The best practice and quality control checks required for preparing a tally are detailed below:

- Check the formulae in the spreadsheet to determine if it is a “casing type” or“liner type” tally (Check also: types of casing).

- The casing is commonly now measured in town using a laser. The laser measurements are generally full joint length (i.e. including threads or “threads on”), some- times may be effective length measurements (i.e. full joint length minus thread length – “threads off”). Check to make sure which was measured and painted on!

- The deck crew recorded the laser measurements that were painted on in town and the running numbers which they painted on when laying the joints out in rows on the rig.

- The DE or Drilling Supervisors should check 1 in 8 of the joints using the rigging tape and compare it with the laser measurements as a QA check. If there are significantly longer or shorter joints than the average, then the lengths of these joints should be double-checked.

- To save time, 1 in 8 of the total joints can be checked from the first row (e.g. check the first 10 joints laid out from 80 total joints).

- Input the measurements provided by the deck crew into the casing liner tally spreadsheet.

- Arrange an independent double-check of the spreadsheet to ensure that the measurements provided by the deck crew have been correctly input into the spreadsheet tally.

- Check the casing tally thread make-up loss length in the sheet.

- Note: the shoe joint does not have any make-up loss applied to it as there are no threads at the bottom of the joint.

- Check the total length of all the joint measurements input into the spreadsheet against the onshore laser measurement total length for all the joints sent to the rig. These two numbers should be the same. If not then either the deck crew has recorded an incorrect laser tally measurement or an incorrect value has been input into the spreadsheet.

- The following quality control checks should be included in the spreadsheet to ensure that the formulae in the spreadsheet are correct:

- Sum the effective length of all tubulars in the tally (including the landing string to the rotary table).

- Record the final depth in hole measurement from the tally.

- Record the final float shoe position.

- All of these numbers should be the same; if they are not then there is a mistake in the formulae in the spreadsheet.